Laserové čištění je vysoce efektivním řešením pro odstranění nečistot z kovových a polymerních materiálů. Jedná se o ekonomickou a vysoce ekologickou alternativu v porovnání s konvenčními čisticími technologiemi, jako je chemické čištění, mechanické broušení, suchý led a ultrazvuk. Technologie umožňuje odstranění velmi odolných reziduí bez ovlivnění podkladového materiálu. Celkový proces je homogenní a vysoce opakovatelný, což prodlužuje provozní životnost čištěných povrchů.

Laserové čištění & povrchová úprava

Modifikace a příprava povrchů

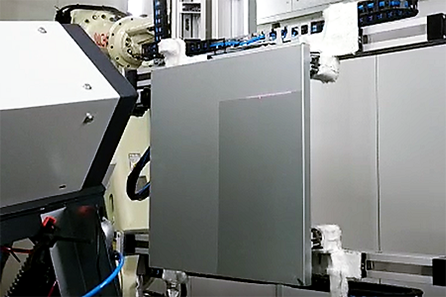

Technologie selektivního odstraňování lakovaných a pokovených vrstev plně nahrazuje složité a zastaralé metody maskování, frézování, broušení a neporovnatelně vylepšuje kvalitu zpracování finálního dílu. Zpracování dílu není omezeno tvarem a jeho povrch je možné plně opracovat i ve 3D prostoru pomocí automatické kontroly polohy a kvality. To vše s opakovatelností až ±0,2 mm do velikosti povrchu dílu 1200 x 1200 m2 na jeden přechod.

Laserové odmašťování

Pomocí laserového čištění je možné velmi účinně předpřipravit celou řadu kovových povrchů a zbavit je tak provozních a konzervačních maziv, olejů, mastnot a přirozeně vznikajících oxidačních vrstev. Čisticí lasery odmastí a kompletně očistí podkladový materiál před následnou úpravou lakováním, lepením, svařováním či dalšími typy spojování. Díky vysoké procesní rychlosti laserového odmašťování je možné opracovávat i velkoplošné díly jako jsou plechy, zárubně a karoserie automobilů.

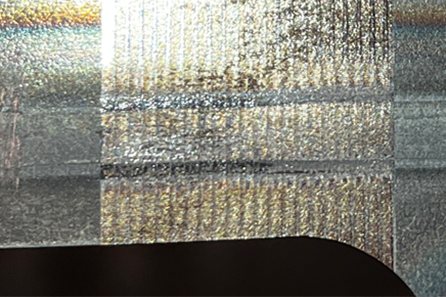

Laserové čištění svarů

Laserové technologie jsou ideální volbou pro čištění svarů, ať už na nerezových a hliníkových materiálech nebo na uhlíkových ocelích. Dokážou spolehlivě odstranit silikáty, mastnoty, nežádoucí zabarvení tepelně ovlivněné oblasti, oxidické vrstvy a jiné nečistoty. Technologie nahrazuje konvenční metody, mezi které patří chemické předúpravy pomocí kyseliny sírové, louhování, mechanické úpravy kartáči a broušení. Proces laserového čištění dosahuje vysoké kvality a rychlosti až 400 mm/s s minimálními energetickými a servisními náklady. Jedná se o další pozitivními benefity, které tato technologie nabízí. Laserové čištění je vhodné pro předúpravu před dalšími technologickými procesy, jako je například lakování.

Laserové čištění závěsové techniky po procesu lakování a pokovení

Laserové čištění je plnohodnotnou ekologickou náhradou konvenčních mycích technologií, mezi které patří vysokotlaké vodní mytí, čištění suchým ledem a pyrolýza při čištění kovových nosičů a závěsové techniky v oblasti automobilového, plastikářského, potravinářského a farmaceutického průmyslu. Proces je realizován výhradně za pomoci plně automatizovaných čisticích linek, kde je díky paralelizaci možné dosáhnout vysoké rychlosti čištění až v řádu 100 000 mm2/s bez sekundárních polutantů.

Laserové odstranění izolačních vrstev

Proces laserového čištění zajišťuje rychlé, přesné a pozičně definované odstranění izolačních vrstev vodičů. Jedná se o plnohodnotnou bezprašnou a ekologickou náhradu stávajících procesů, kterými jsou broušení nebo frézování. Unikátním přístupem dvoufázového čištění dosahujeme kvalitní přípravy povrchů pro přímé použití v následujícím procesu svařování nebo cínování bez potřeby předúprav, jako jsou odmašťování nebo chemická úprava.

Pro plastikářský průmysl nabízíme řešení laserový decoating a laserový etching.

Produkty a produktové platformy

Hlavní vlastnosti a výhody

- Bezkontaktní CO2 neutrální proces

- Nenáročná údržba

- Plnohodnotná náhrada konvenčních technologií

- Snadná implementace

- Minimální nároky na prostor

- Přímé použití opracovaného povrchu k dalším výrobním procesům